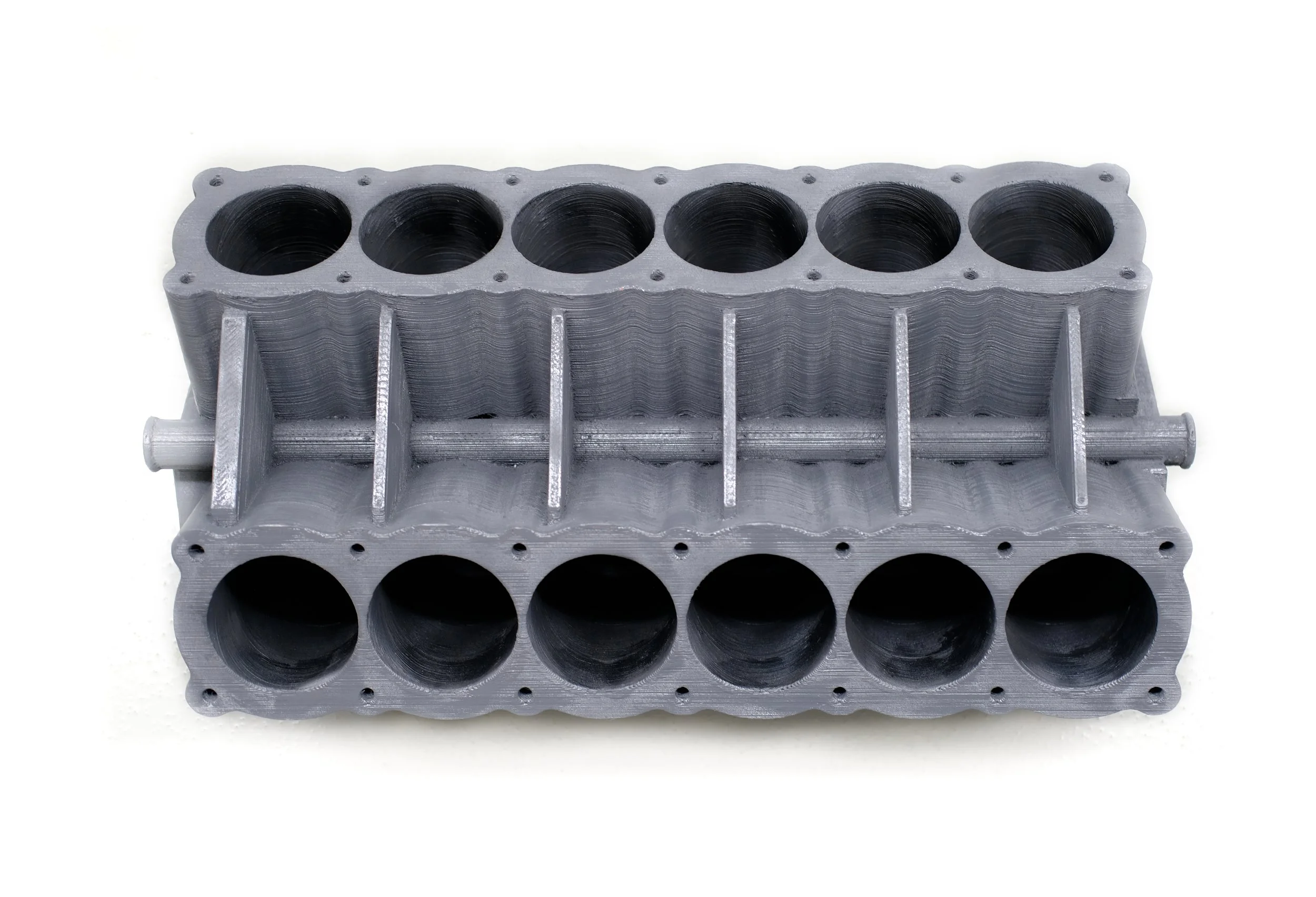

Mock Up V12

When you think of 3D printed cars, you probably think of a 3D printed chassis, not the engine itself.

We built a V12 engine and debuted it at Syracuse Nationals in 2022, the largest car show in the Northeast. This one-piece block is not aluminum or cast iron, it’s printed. Fully 3D printed on our massive professional printer the Vault.

Within our giant chamber of 7ft x 5ft x 5ft, The Vault prints full size and custom parts, standing in an additive manufacturing league of its own.

With the cavities and detailed parts, 3D printing a full size V12 engine block like this, would take an unreasonable amount of time on anything smaller than our XXL printer. It was no challenge at all for our massive printer, the Vault, one of the largest 3D printers in the Americas.

Mock up transmissions, motors, and engines make sense. No need to drag out your cherry picker to fit the block into the car. No need to guess if this part fits or not. Working on your car doesn’t need to be harder than it already is.

With this fully functional 3D print, you can now check how the V12 engine fits and at the same time, complete hours of sub-assembly work. The engine block is light and easy to work with. It won’t break your back, scratch your paint, or pinch your fingers. Plus when you’re finished with the part, it can easily be stowed away in your attic, something you can’t do with metal parts.

Here at Think Variant, we have also 3D printed other automotive component parts: such as an intake valve, oil pan, valve cover, Rx7 tire cover, to name a few.

3D printed mock-up engine blocks are invaluable and no challenge at all for the Vault.